vicky.james@brianhyde.co.uk 30/10/2018 14:36:21

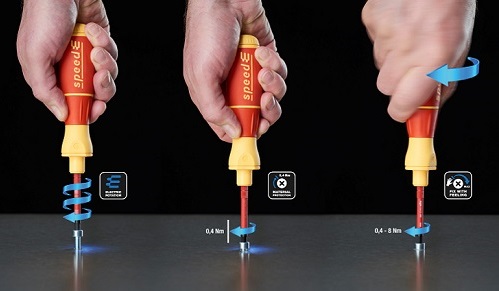

“Drive with speed, fix with feeling” – as the first e-screwdriver from Wiha, speedE® promises to halve the time users take to complete their work in the future. An electric motor assists with fastening screws up to 0.4 Nm before disengaging to ensure that material is protected. The screw can then be fixed by hand with a deft touch, just as with a conventional screwdriver. An innovative electric ratchet function assists users as they complete fastening. The globally unique 3-step speedE® process enables users to work significantly faster and more efficiently, but by using a controlled, healthier technique.

“Drive with speed, fix with feeling” – as the first e-screwdriver from Wiha, speedE® promises to halve the time users take to complete their work in the future. An electric motor assists with fastening screws up to 0.4 Nm before disengaging to ensure that material is protected. The screw can then be fixed by hand with a deft touch, just as with a conventional screwdriver. An innovative electric ratchet function assists users as they complete fastening. The globally unique 3-step speedE® process enables users to work significantly faster and more efficiently, but by using a controlled, healthier technique.

Thanks to its electric drive, the Wiha e-screwdriver handles time-consuming, energy-sapping screw-fastening at a rapid rate, significantly faster than conventional means. Compared to manual screw-fixing, speedE® helps users get things done at least twice as fast, increasing their working day efficiency substantially with more comfort. speedE® also allows users to take a healthier approach to work while saving their strength.

View the Wiha speedE here

Even so, they can adjust or fasten by hand with a deft touch using up to 8 Nm when the integrated material protection function activates at 0.4 Nm. The speedE® can thus also be used as a fully-fledged screwdriver, in combination with the Wiha VDE-tested and insulated slimBits, completely protected for use and work on live parts. This consciously fine-tuned power transmission and torque control in electric mode brings a particular benefit to users for delicate screw-fastenings. A constantly changing grip for manual screw-fastening becomes a thing of the past while the electric ratchet function helps to make work methods more efficient while preserving health. An integrated LED light also ensures users are not left in the dark as they fasten screws.

Even so, they can adjust or fasten by hand with a deft touch using up to 8 Nm when the integrated material protection function activates at 0.4 Nm. The speedE® can thus also be used as a fully-fledged screwdriver, in combination with the Wiha VDE-tested and insulated slimBits, completely protected for use and work on live parts. This consciously fine-tuned power transmission and torque control in electric mode brings a particular benefit to users for delicate screw-fastenings. A constantly changing grip for manual screw-fastening becomes a thing of the past while the electric ratchet function helps to make work methods more efficient while preserving health. An integrated LED light also ensures users are not left in the dark as they fasten screws.

Comparable to normal screwdrivers in terms of size and weight, the first Wiha e-screwdriver is an ideal, portable companion in an extensive variety of sectors and application areas with its compact, lightweight design. speedE® also provides users with maximum flexibility since they can use all available drives in the Wiha slimBit range to fasten electrically. All Wiha VDE slimBits are compatible with speedE®, are tested to 10,000 V AC, all undergo inspection and are individually tested for up to 1,000 V AC.

When fully charged, speedE® can fasten electrically up to 800 times. In an ideal case, this provides users with a time frame of over several days to work with the Wiha e-screwdriver without re-charging the batteries. Standard rechargeable batteries inside the handle eliminate follow-up costs, which highlights speedE®'s user-friendly approach.

Ronny Lindskog, Sales and Marketing Manager at Wiha, explains: "As a pioneer in its type, speedE® is marking a new milestone in the further development of fastening tools not only at Wiha. speedE® is in a class of its own. The possible scope and potential for this invention for users, retail and the whole sector are huge."

The Wiha speedE® will be available to HYDE customers in three starter set variants with the ideal set depending on requirements and tasks. Besides the electric screwdriver, sets include two rechargeable batteries, a portable battery charger, a sturdy Sortimo L-BOXX to carry everything and an assortment of suitable slimBits and easyTorque torque adapters with content depending on the variant.

"speedE® unites maximum standards in quality, design, ergonomics, functionality and durability. A great deal of practical experience, an intensive development stage and several user surveys have ultimately allowed us to achieve a breakthrough, of which we are very proud. speedE® is now able to conquer the world. It is very much ready," concludes Lindskog.

View the new speedE from Wiha here or contact HYDE for more details.

From the Wiha newsroom Link